We manufacture a wide variety of sheet metal processing equipment, including heavy-duty press brakes capable of bending sheets over 30mm thick and high-power laser cutting machines that handle materials such as 20mm carbon steel, 50mm stainless steel, and 40mm aluminum. Our products meet international certification standards, ensuring top-tier quality and reliability.

All CNC equipment is designed for automated programming and high-precision operations. Operators can input parameters such as bending angles, cutting lengths, and repetition cycles through an intuitive human-machine interface. The system then executes precise cutting and bending in a short time. Additionally, our machines can be seamlessly integrated into automated production lines for increased efficiency.

To meet specialized industry demands, we design and manufacture custom press brakes and laser cutting machines. For instance, our heavy-duty press brakes are reinforced for ultra-thick plate bending, handling extreme pressure with structural enhancements. We also offer laser cutting machines for non-traditional shapes, utilizing advanced mechanical structures for complex and irregular designs.

The business department has about 15 employees, mainly responsible for the design, sales and testing of tools. They have many years of experience in sheet metal industry and especially have unique insights into the adaptation of different brands of press brakes and the design of special forming tooling.

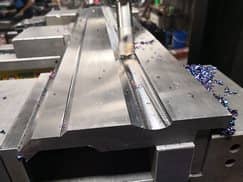

Planing Machine for Rough-Plane of V Groove

Planing Machine for Rough-Plane of V Groove Flat Grinder for Coarse Grinding of V Groove

Flat Grinder for Coarse Grinding of V Groove Ram Milling Machine for Fine Milling of Cavity

Ram Milling Machine for Fine Milling of Cavity Mould Machining by Milling Machine

Mould Machining by Milling Machine Finish Milling of Top Tool Bevel

Finish Milling of Top Tool Bevel Finish Milling of Heat-Treated Bent Blade

Finish Milling of Heat-Treated Bent Blade Nc Fine Grinding of Double V Groove

Nc Fine Grinding of Double V Groove Fine Grinding of Reinforcement Mould

Fine Grinding of Reinforcement Mould Fine Grinding of Top Tooling Blade

Fine Grinding of Top Tooling Blade Plane Polishing

Plane PolishingOur machining workshop is equipped with different sizes of planing machines, grinding machines, milling machines, CNC centers and press brake for tools testing. The annual production capacity is about 300, 000 molds (835mm for each pcs). The delivery of standard mold is 1 week, and the delivery of custom mold is about 25 days.

Our company has various pieces of inspection equipment to ensure that the hardness, straightness, and flatness of the tooling are perfect for the major brands of press brakes.