We provide a full range of advanced sheet metal machinery, tailored to the evolving needs of the industry. Our selection includes panel bending machines, fiber laser cutting systems, and precision bending equipment. Every sheet metal processing machine undergoes rigorous quality control to ensure consistent accuracy, efficiency, and reliability in production.

The single electric cylinder design makes for a relatively simple and low-cost machine, suitable for small production plants or environments that require flexible operation, usually for smaller workpieces or simple bending tasks.

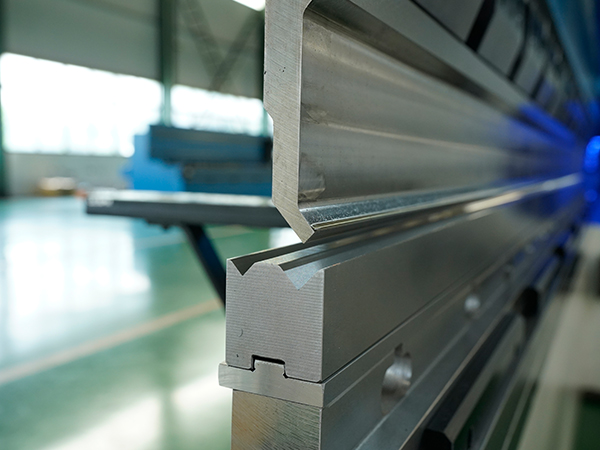

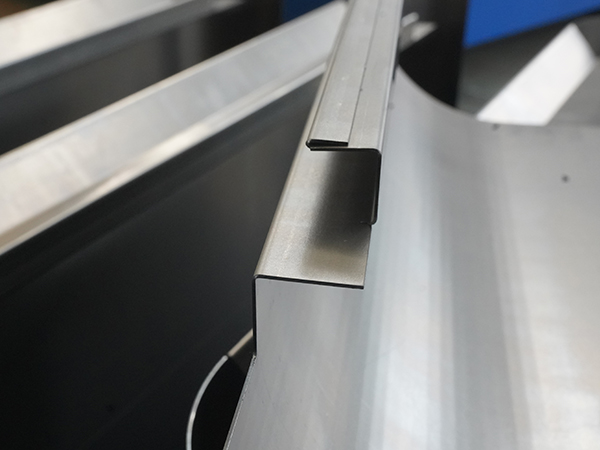

Flexible Bending Centre focuses on solving various complex sheet metal and bending problems in metal forming. By linking multiple axes in parallel and automatically completing sheet metal work...

Fangwei can provide customers with many types of laser cutting machines.

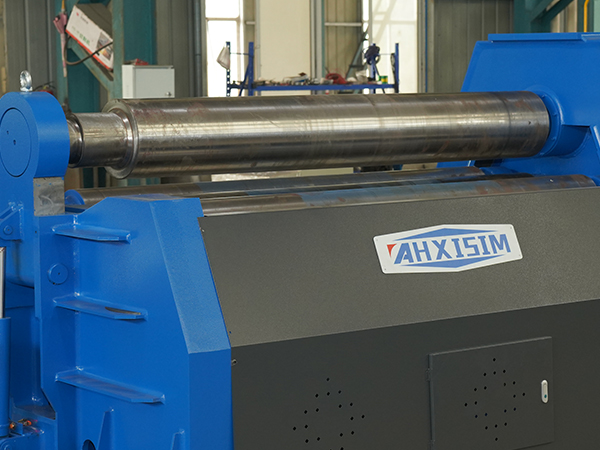

Plate rolling machine is a kind of equipment that uses working rollers to make plate bending and forming, and it can form different shapes of parts such as cylindrical parts, conical parts and so on. The working principle of the coiler is to make the working roll move through the action of hydraulic pressure, mechanical force and other external forces, so as to make the plate bending or roll bending forming.

The machine is an all-steel welded mechanism with hydraulic up-drive and vibration stress relief, which makes the machine of high strength and good rigidity. Hydraulic pendulum shear is by using the main cylinder (fixed on the wall plate) to do downward shear movement, nitrogen cylinder return, so simplify the hydraulic system, more stable operation.